Thread Classes

Table of Contents

What Are Thread Classes?

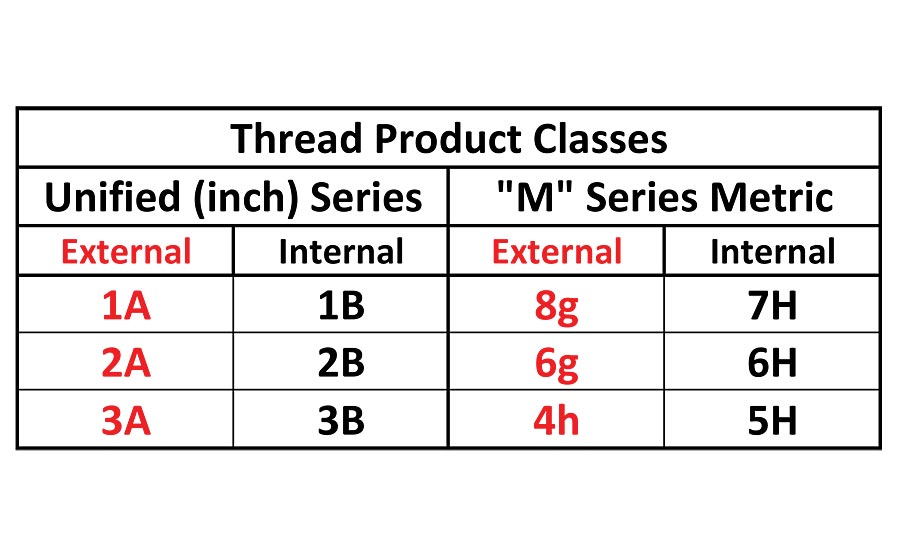

Thread classes designate the fit of a specific fastener. When talking about Unified inch screw threads, there exists six standard classes of fit: 1B, 2B, 3B, 1A, 2A, and 3A. A lower class number designates a looser fit and a higher number designates a tighter fit [1]. The class letter 'A' determines an external thread such as on a bolt and the letter 'B' determines an internal thread such as on a nut [1]. These are all considered clearance fit because they provide an assembly without interference whereas an interference fit would allow positive interference of the screw with the hole. An example of a UNF series thread's designation can be seen in Figure 1.

Metric variants of these thread classes also exist. They can be seen in Figure 3 to the right with the corresponding UNF Series to the left. The letter signifies the thread band (lower case for external threads and upper case for internal threads) and the number signifies the tolerance grade, a higher number being a looser fit and a lower number being a tighter fit. Metric threads have an additional feature where they can state a tolerance grade and position for both the pitch diameter and the major diameter for external product threads and minor diameter for internal product threads [2]. An example of a metric thread's designation can be seen in Figure 2.

Figure 1. UNF Thread [2] | Figure 2. Metric Thread [2] |

|---|---|

Figure 3. Thread Classes [2] |

|---|

Screw Thread Fundamentals

Screw Thread

Defined as a ridge of uniform section in form of a helix on the inside or outside of a cylinder.

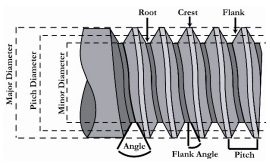

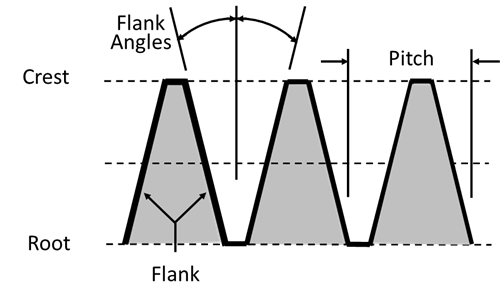

Thread Form

Configuration of the thread in an axial plane composed of the crest, root, and flank. At the top of the threads are the crest, at the bottom are the roots, and in between them are the flanks. The triangle created when extending the thread profile at a point on both the crest and root is called the fundamental triangle.

Figure 4. Components of a Thread [1] |

|---|

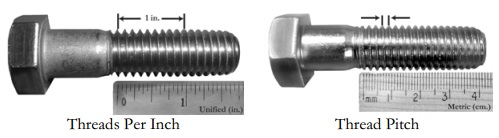

Thread Pitch

The distance between two points measured parallel to the thread axis is the thread pitch. Unified screw threads are designated in threads per inch which is the number of threads in one inch of the thread.

Figure 5. Thread Pitch [1] |

|---|

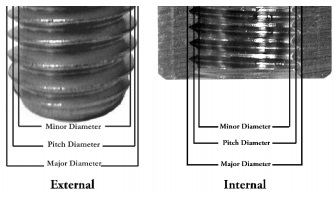

Internal vs External Threads

Internal threads are bolts, studs or screw threads while internal threads are the threads on nuts or tapped holes that goes on the bolt. Internal and external threads can also be referred to as female and male, respectively. This property is known as gender. On internal threads, the minor diameter is the diameter of the thread from root to root, while the major diameter is the diameter from crest to crest. The pitch diameter is the theoretical diameter of a cylinder that passes through the threads such that the distance between the crest and roots is equal. In an ideal product, this should be equal to one-half of the thread pitch.

Figure 6. External vs Internal [1] |

|---|

Flank Angle

The angle between the flank and a line perpendicular to the axis of the thread. Flank angles may be referred to as half-angles of the thread, but only when neighboring flank angles are symmetrical.

Figure 7. Flank Angle [5] |

|---|

Thread Fit

A thread fit is defined as a combination of allowances and tolerances as well as a measure of tightness/looseness between an external and internal pair of threads.

Classes of Fit

There are six standard classes of fit for Unified screw inch threads, 1B, 2B and 3B for internal threads, and 1A, 2A, and 3A for external threads where the number refers to their tightness. Thread limits which are denoted as H for inches, and D for metric is a standard notation system that indicates the level of tolerance. [15]

Classes 1A and 1B | Classes 2A and 2B | Classes 3A and 3B |

|---|---|---|

| These include threads of extremely loose fit. This thread class is rarely used or specified in any commercial or industrial environments. They are not meant as a permanent solution to any structures due to safety purposes and are only used for quick and easy assembly. | Threads of this fit offer optimal fit. They are a balance between performance, manufacturing, cost and convenience. About 90% of all industrial and commercial fasteners use this class of fit. Most fasteners sold at any major retailer would be found at this thread fit. | Threads of class 3 are best suited where strict tolerances and strength are required. Therefore they are mostly used when safety is a critical design consideration. An instance of this thread fit would be socket caps and socket set screws [1]. |

Figure 8. Relationship of Pitch Diameter Allowances and Tolerances [1] |

|---|

Thread Series

In the Unified screw thread system, there are three important standard thread series for fasteners, UNC/UNRC (coarse), UNF/UNRF (fine), and 8-UN (8 thread). [1]

| Fine | Coarse | 8 Thread |

|---|---|---|

|

|

|

Figure 9. Fine vs Coarse Thread [1] |

|---|

UNR Threads

UNR thread is a modified version of a standard UN thread, where the only difference is a mandatory root radius with limits of 0.108 to 0.144 times the thread pitch. In the past, it was required to specify UNR threads, but fasteners today that are roll threaded meaning that the thread was created by extruding steel to form the threaded portion of the fastener should have a UNR thread as they are now the standard [1]

UNJ Threads

UNJ thread is a thread form which has a root radius limit of 0.150 to 0.180 times the thread pitch. With this enlarged radius, minor diameters of external thread increase and intrude beyond the profile of the UN and UNR thread forms. To counteract the possibility of interference between threads, the minor diameter of UNJ internal threads is increased. UNJ threads have become the standard for aerospace fasteners and are used in certain highly specialized industrial applications. [1]

Thread Forms in Use

| Thread Form | Image [6] | Description | Usage | Standard |

|---|---|---|---|---|

British Standard Whitworth |

|

| ||

Metric (S.I.) |

|

|

| |

British Standard CYCLE |

|

| ||

British Association |

|

| ||

ISO Metric/ISO Inch Unified |

|

|

|

References

[1] “Screw Threads,” Fastenal, 04-Mar-2009. [Online]. Available: https://www.fastenal.com/content/feds/pdf/Article%20-%20Screw%20Threads%20Design.pdf. [Accessed: 29-Jan-2021].

[2] M. Oddy, “Thread Classes and Setting Plug Gages,” Quality Magazine RSS, 29-Sep-2019. [Online]. Available: https://www.qualitymag.com/articles/95710-thread-classes-and-setting-plug-gages. [Accessed: 29-Jan-2021].

[3] “Can you explain ‘Thread Class’?,” Accurate Screw Machine (ASM), 23-Oct-2017. [Online]. Available: https://www.accuratescrew.com/classes-of-thread/. [Accessed: 29-Jan-2021].

[4] B. Warfield, cncdivi on 2018/04/02 at 8:14 am Bruce, and N. *, “Easy Thread Terminology Guide to 36 Essential Terms [2018],” CNCCookbook, 03-Feb-2021. [Online]. Available: https://www.cnccookbook.com/easy-thread-terminology-guide-2018/. [Accessed: 16-Feb-2021].

[5] Posted bySteve Toll on and S. Toll, “Thread Inspection 101 Part II - Thread Form,” Fox Valley Metrology, 26-Jun-2019. [Online]. Available: https://www.foxvalleymetrology.com/blog/posts/2019/june/thread-inspection-101-part-ii-thread-form/. [Accessed: 25-Feb-2021].

[6] “Thread Forms In Common Use: Thread Check,” Threadcheck. [Online]. Available: https://www.threadcheck.com/thread-forms/. [Accessed: 04-Mar-2021].

[7] “British Standard Whitworth,” Wikipedia, 11-Feb-2021. [Online]. Available: https://en.wikipedia.org/wiki/British_Standard_Whitworth. [Accessed: 04-Mar-2021].

[8] “Types of threads (III) – metric thread: Products: Blog,” rmmcia. [Online]. Available: http://www.rmmcia.com/blog/types-threads-iii-%E2%80%93-metric-thread. [Accessed: 04-Mar-2021].

[9] “British Standard Cycle,” Wikipedia, 11-Feb-2021. [Online]. Available: https://en.wikipedia.org/wiki/British_Standard_Cycle#:~:text=British%20Standard%20Cycle%20(BSC%20or,than%20a%2055%20degrees%20angle. [Accessed: 04-Mar-2021].

[10] “British Association screw threads,” Wikipedia, 10-Jul-2020. [Online]. Available: https://en.wikipedia.org/wiki/British_Association_screw_threads#:~:text=British%20Association%20screw%20threads%2C%20or,for%20miniature%20instruments%20and%20modelling. [Accessed: 04-Mar-2021].

[11] “ISO metric screw thread,” Wikipedia, 16-Mar-2021. [Online]. Available: https://en.wikipedia.org/wiki/ISO_metric_screw_thread. [Accessed: 17-Mar-2021].

Contributors:

| User | Last Update |

|---|---|

| Lesley Lang | 1189 days ago |

| Former user (Deleted) | |

| Former user (Deleted) | |

| Former user (Deleted) | |

| Former user (Deleted) |

Faculty Advisor: Chris Rennick and Michael Lenover (alumni)